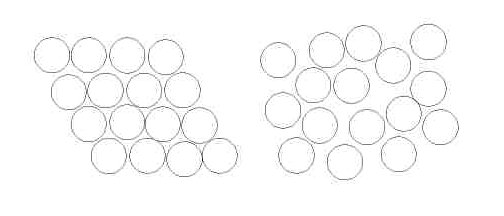

Glasses or amorphous materials are frozen-in liquids, i.e. atoms / molecules are distributed

haphazardly throughout the material, without any periodic order as shown in Fig. 1(b).

(a) Crytalline (b) Amorphous

Fig. 1

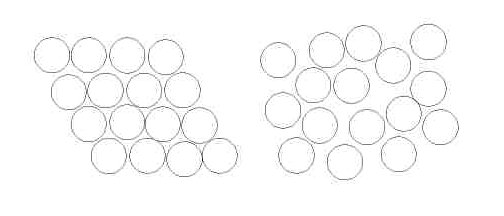

Glasses or amorphous materials are frozen-in

liquids, i.e. atoms / molecules are distributed

haphazardly throughout the material, without

any periodic order as shown in Fig. 1(b).

(a) Crytalline

(b) Amorphous

Fig. 1

The glasses may be catagorized into 3 distinct species as to their ease of formation:

:-

Metallic glasses: are obtained by rapidly quenching from metallic

melts,

e.g. Mg-Zn,

Fe-B glasses etc; if the metallic melts are not cooled fastly,

they crystallize

to form crystalline solids.

:- Inorganic

glasses: are obtained by moderately cooling from the melts of

inorganic materials, .e.g. silicates. For crystallization, their melts

have to

be cooled very slowly, otherwise they will solidify as amorphous.

:- Organic

glasses: are obtained from organic material melts some of which

never crystallize whatever the cooling rate.

The crystallization behaviour ( phase analysis

at crystallization) is usually studied

by thermal analysis methods, e.g. differential

thermal analysis (DTA), differential

scanning calorimetry (DSC). In these methods

the heat of crystallization stored in

glass is given up at the crystallization temperature,

which is then registered as a peak

in the dT versus time (t) or Cp versus temperature

(T) curves, where dT = Ts-Ti.

Ts and Ti are temperatues of the sample and an

innert substance. A disadvantage

of the thermal analysis methods in phase analysis

is that no structural information

about the crystallization products is deciphered.

Structural information about the crystallization

products may be secured by taking

at room temperature x-ray diffraction patterns

of the glass samples tempered at

different temperatures. However, by this static

temeprature x-ray diffraction analysis

a lot of valuable information about the crystallization

mechanism remains hidden.

To decipher the phase formation at and after crystallization

of a glass, the best

method would be to continuously register the

x-ray diffraction pattern during

continuously heating the glass sample, i.e. recording

a dynamic temperature x-ray

diffraction (DTXD) pattern of the glass sample

under study. The author has

developed a DTXD apparatus [cf. J. Phys: Sci.

Instru. 85 (1985)1054] in his

laboratory and investigated a number of metallic

and inorganic glasses.

DTXD patterns of important glasses e.g.

:-

MgZn30

(Liquid Quenched)

:-

CoB18

(Liquid Quenched)

:- CoB18

(Vapor Deposited)

:-

CoB25

(Liquid Quenched)

:-

FeB25

(Liquid Quenched)

:-

PdSi13

(Liquid Quenched)

:-

Sm2(CoB25)98

(Liquid Quenched)

:-

Sm4(CoB25)96

(Liquid Quenched)

:-

ZrFe12Si2B

(Liquid Quenched)

:-

Zr1.67Fe12Si2BZr

(Liquid Quenched)

:-

Bi4SrSCa2Cu4O14

(Liquid Quenched)

demonstrate the usefulness of this technic for structural analysis.

The potential of the DTXD method lies in the fact that continuity of

the X-ray

diffraction lines reveals a lot of minute, hidden details about the

crystallization

and post crystallization behaviour of glasses and melts not accessible

by other

means, e.g. it is believed that X-ray diffraction halo of glasses is

not structured,

but smooth and homogeneous in intensity. DTXD analyses show that it

is only

true for those glasses which do not contain X-ray absorbing atoms,

i.e. the

structure of the amorphous halo depends upon the absorption coefficient

of the

constituents of the glass under study; the higher the absortion coefficient

of the

glass constituents, the more structured is the halo, see for example

DTXD

patterns of CoB25, Sm2(CoB25)98

and Sm4(CoB25)96;

it can be seen that halo

is structured into bands, structuring increases with increasing content

of Sm

due to L-absorption edge of Sm at CoKa wavelength. This effect can

be used

to find atomic pair distances in amorphous materials.

Another important result of DTXD analysis of glasses is that a glass

crystallizes

in the reverse order of the phase diagram, i.e. the phase or phases

crystallizing

first from the liquid state also crystallize from the amorphous state

as can be from

the above mentioned DTXD photographs, leading to the conclusion that

it is hardly

conceiveable to accept that glasses are undercooled liquids. DXTD results

obtained

so far support the scenario: liquids, which tend to undercool, cannot

form glasses.

Question arises why some melts soldifiy to form glasses other crystallize

what ever

the cooling rate. A detailed DTXD study of Mg-Zn

glasses revealed that those

systems are prune to glass formation, which show multimorphy

( polymorphy and

merimorphy taken together), i.e. a phase exits in a large number

of crystal structures

of the same type as a function of state parameters temperature, pressure

and concen-

tration. The greater is the multimorphicity of a compound, the higher

is the glass-

forming ability of that compound. If the melt of a multimorphous compound

is cooled,

one or the modification forms depending upon the state parameters.

In case of Mg-Zn

system, a new phase modification forms, if the temperature of the melts

is raised a few

degrees above the regular melting temperature. Further details are

given in the referen-

ces cited in the headings of the DTXT photos discussed above.

For questions and support drop me a mail ( University

/ Privat )